High Pressure Equipment Company:

HiP is a leader in the production of components and pumps for industries with high pressure applications.

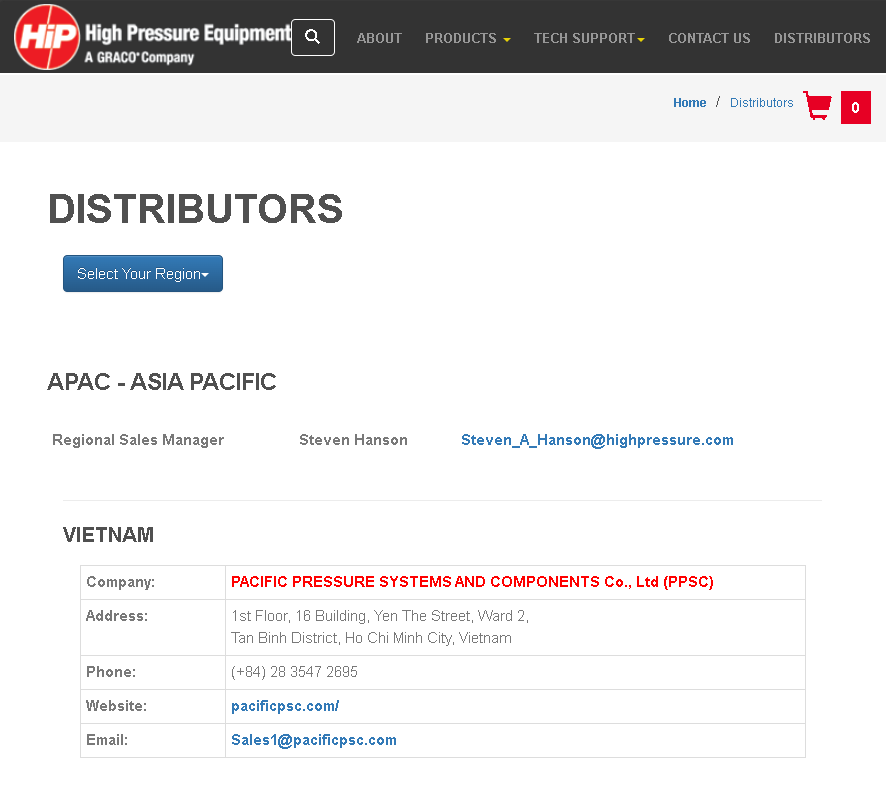

Official distributor in Vietnam:

Pacific Pressure Systems & Component Co., ltd (PPSC) is currently cooperating as well as being the official distributor.

Access high quality products:

Being an authorized distributor allows us to provide our customers with access to the best hydraulic and high pressure products on the market.

Quality assurance:

You can rest assured of top quality SPIR STAR products, backed by our unwavering dedication to customer satisfaction and outstanding service.

PRODUCT LINE

T- SERIES HIGH PERFORMANCE AIR-DRIVEN PUMPS

High Pressure Equipment’s new T-Series pneumatically operated liquid pumps offer a safe, reliable, and durable hydraulic power source for applications up to 68,000 psi (4,688 bar). Combining HiP’s high pressure expertise with Graco’s pump engineering, T-Series pumps overcome common issues in air-driven liquid pumps. They run at maximum pressure, have a robust motor and seal design for long life, do not require lubricated air, and are easy to install and service.

AIR DRIVEN LIQUID PUMP

Sprague Products developed the first air-operated liquid pump in 1947 for aerospace hydrostatic testing. This positive-displacement design became the foundation for high-pressure hydraulic pumps used in various industries, including aerospace, oil and gas, and manufacturing. The Sprague pump converts low-pressure air into high hydraulic pressure using a large air-driven piston to drive a smaller liquid piston. It operates rapidly until liquid pressure reaches the desired level, then slows to a stop, maintaining balance with minimal energy use. The pump restarts automatically if pressure drops or air-drive pressure increases, offering efficient, cost-effective, and energy-saving benefits.

AIR DRIVEN GAS BOOSTER

Sprague’s T-Series packaged hydraulic power systems deliver up to 68,000 psi using a non-lubricated air supply and are suitable for water or oil service. Standard and custom power packs are available, factory pressure tested, and ready for various high-pressure applications, including bolt tensioning, pressure testing, jacking, lifting, and valve actuation.

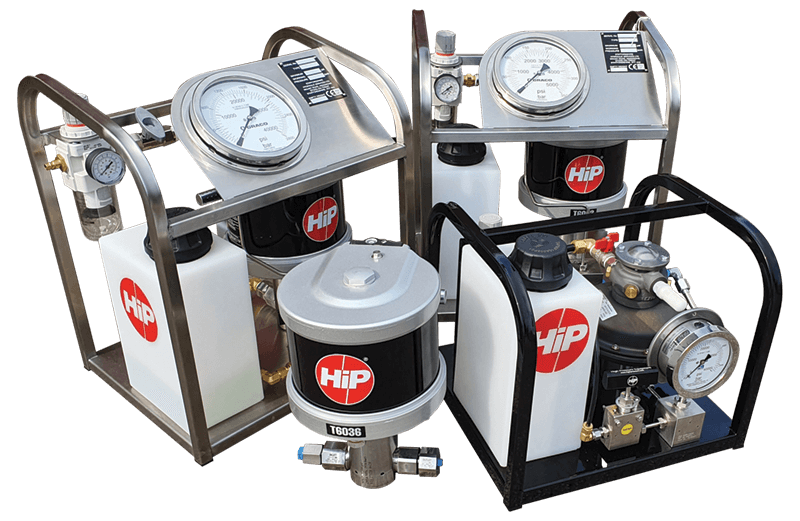

PUMP SYSTEMS POWER PACKS

HiP packaged hydraulic power systems using our new high-performance T-Series pumps are an excellent method to deliver high pressure hydraulic power to your field location. These turn-key systems only require a non-lubricated air supply to generate hydraulic power up to 68,000 psi and are designed for plain water or oil service. We offer a range of standard power packs that are typically in-stock or available with a short lead time, as well as custom power systems to satisfy your specific requirements. All HiP power packs are factory pressure tested prior to shipping.

HOW IT WORKS

- The pump has a large area air piston driven at low pressures.

- This air piston drives a small area liquid piston.

- The small area liquid piston pumps liquids at high pressures.

- The liquid output pressure is determined by:

- The ratio between the area of the air drive piston and the area of the liquid driven piston.

- The applied operating air pressure.

- The area relationship of the air piston to the liquid piston is called the pump ratio.

- The pump ratio is indicated in the dash number following the pump model basic number

WHY SPRAGUE

- One of the highest technology air motors on the market

- Low air consumption for increased efficiency

- Proven technology with over 10 years in the market

- Heavy duty muffler provides low operating sound levels

- External valve access allows for easy servicing to help minimize downtime

- Pump can achieve the maximum working pressure time and time again unlike intermittent duty rated pumps

No need for additional mufflers - Severe duty plunger seal for less downtime

- Can service air motor shuttle valve without disassembling the pump

- Quick and easy access to plunger seals

- Minimal tools required

- Separated pump air section helps prevent fluid leaks into air motor

- Inlet/outlet connections match pipe connections

- Bubble tight checks

Hydrostatic Testing Applications: Sprague air-driven pumps offer cost-effective pressure testing for hoses, pipes, valves, fittings, and hydraulic vessels, converting tedious hand-pump methods to automatic, precise testing.

Production Machinery Applications: Sprague pumps deliver high-pressure liquids for production machinery tasks like holding, clamping, forming, shearing, and punching. They can combine high and low volume pumps for efficient, high-speed, high-force operations at low cost.

No Need for Central Power Source: Compact Sprague pumps can be installed directly on individual machines, eliminating the need for a central power system, long plumbing runs, and excess hydraulic capacity.

Safe Operation: Sprague air-driven pumps are non-arcing and non-sparking, safe for use in hazardous or confined areas.

Simpler Maintenance: Sprague pumps have fewer parts and seals, making maintenance simpler compared to other air-driven pumps.

- Works off compressed air supplies

- Operates quietly

- Features mechanical separation between air drive and boosted gas

- Compatible with most gases

- Principles of Operation: The PowerStar™4B gas booster uses the differential piston area principle. A large piston driven by low air pressures drives a small compression piston to convert input gas to higher pressure. The output pressure depends on the drive piston's area, operating air pressure, and precharge pressure.

- ctual Operation: The PowerStar™4B starts rapidly, then slows and stops at pressure balance, maintaining it indefinitely without leakage. It restarts automatically if there's a pressure imbalance. Exhaust air from the air drive cools the high-pressure chamber.

Gas Booster in Action: The PowerStar™4B optimizes the use of commercially bottled gas, ideal for applications needing gas above normal cylinder pressure or continuous high pressure. Some units can also draw a vacuum.

- HiP packaged hydraulic power systems deliver high-pressure hydraulic power to field locations.

- Utilize new high performance T-Series pumps.

- Require only a non-lubricated air supply.

- Generate hydraulic power up to 68,000 psi.

- Designed for plain water or oil service.

- Range of standard power packs in stock or with short lead time.

- Custom power systems available for specific requirements.

- All power packs are factory pressure tested before shipping.

High pressure testing applications including but not limited to BOP Stacks, choke and kill lines, Christmas trees, valves, pipelines, hoses, cylinders, pressure vessels and components, valve actuation and any other type of equipment requiring high-pressure static testing. The test units may be provided in working pressure ranges up to 50,000 PSI and are safely tested with its compact easy to operate and friendly control panel design. Units are self-contained and operated by low pressure shop air or optional from high pressure Nitrogen cylinders.

A variety of Sprague and PowerStar™ pumps are available as packaged systems with output pressures up to 36,500 psi. These air driven power units are designed for portable and stationary applications and delivered fully assembled, ready-to-use and factory tested.

- Filling air tanks from larger cylinders

- Testing air pressure regulators

- Gas mixing

• Filling breathing air cylinders

• Mobile filling stations for firefighters

• Halon and CO2 charging

O2 charging of self-contained, self-rescuer (SCSR) devices, O2 charging of 47-liter bottles, pressure testing, gas transfer and recovery, and the charging of nitrogen accumulator....

- Air bag testing

- Gas spring charging systems for die and mold manufacturers

- Accumulator charging